We have more than 200 records in these fields

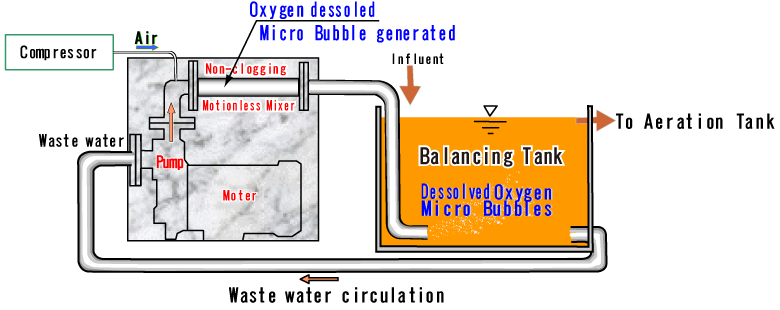

Waste Water Pre-Processing Treatment System

- This is a system which consists of non-clogging motionless mixer,pump and compressor,and by which

oxygen is dissolved efficiently and micro-bubbles are generated uniformly in wastewater. - This is applied for the aerobic treatment of wastewater, especially industrial wastewaster.

- This can be placed at existing balancing tank without any large-scale reconstruction.

- This can result in the reduction and leveling of wastewater influent loading (BOD,COD,SS N-Hex). Microorganisms are diversified, then wastewater treatment are stabilized and biosludge can be reduced 20 to 30% on average.

- Low running cost (only electric power needed). High quality operation and maintenance like MBRs is not needed.

■About WasteWater Pre-Processing Treatment System

●Examples

- 【Hormone Prepared Foods Plant】

- 【Confectionery Factory】

- 【Mayonnaise/Dressing Plant】

- 【Miso/Soy Sauce Factory】

- 【Japanese Confectionery Plant】

- 【Poultry Processing Plant】

Hormone Prepared Foods Plant

【Stabilization of waste water treatment and No-need of Pressure Floatation Unit】

After installation of this system, they have gotten money saving and work reduction..

Routine work have been reduced significantly.

Daily work is only inspection

of the lubrication oil, and drainage of compressor .

- ・Influent flow

- 120t/d ⇒180〜200t/日(After USA/Σ-Aero Installed)

- ・BOD

- 2,000mg/L

- ・SS

- 1,000mg/L

- ・N-hex

- 220mg/L

- ・BOD Loading Rate

- 0.86kg・BOD/㎥・d ⇒1.43kg・BOD/㎥・d(After USA/Σ-Aero Installed)

- ・SV30

- 98% ⇒85%(After USA/Σ-Aero Installed)

Confectionary Factory

- ・Influent flow

- 250t/d(Sum of two kind of Influent)

- ・BOD

- 2,500mg/L(Higer Concentration)

- ・SS

- 500mg/L

- ・N-hex

- 360mg/L

- ・BOD Loading Rate

- 0.7kg・BOD/㎥・d(per Gross Influent)

- ・Excessive Bio-Sludge

- 100% ⇒70〜80%(After USA/Σ-Aero Installed)

Mayonnaise/Dressing Plant

- ・Influent flow

- 1,000t/d

- ・BOD

- 1,200〜2,600mg/L

- ・SS

- 140〜450mg/L(Average:300mg/L)

- ・N-hex

- 360〜150mg/L(Average:90mg/L)

- ・BOD Loading Rate

- 1.3kg・BOD/㎥・d(Average of analysis value)

Miso/Soy Sauce Factory

- ・Influent flow

- 150〜200t/d

- ・BOD

- 3,000mg/mg/L

- ・SS

- 1,000〜2,000mg/L

- ・BOD Loading Rate

- 1.6〜2.1kg・BOD/㎥・d

- ・Effluent into Sewer

- (BOD,SS)300mg/L (N-Hex)30mg/L

Japanease Confectionary Plant

- ・Influent flow

- 250t/d(Candy 100t/d, Beans and Gummy 150t/d)

- ・BOD

- 8,000mg/mg/L(Candy14,000mg/L, Beans and Gummy4,000mg/L)

- ・SS

- 1,360mg/L(Candy550mg/L, Beans and Gummy1,900mg/L)

- ・N-hex

- 176mg/L(Candy260mg/L, Beans and Gummy120mg/L)

- ・pH

- 4.2〜5.8

Poultry Processing Plant

- ・Influent flow

- 500t/d

- ・BOD

- 3,000mg/mg/L

- ・SS

- 2,000mg/L

- ・N-hex

- 800〜1,200mg/L

- ・BOD Loading Rate

- App.2.0kg・BOD/㎥・d

- ・Effluent into the Rever